Stock Symbol | 835427

- HOME

- About Us

-

Products

Sustainable Kaifeng

Sustainable Kaifeng -

Innovation

Sustainable Kaifeng

Sustainable Kaifeng - Global Layout

- Vibrant Kaifeng

- CONTACT US

Zhejiang Kaifeng new material co., LTD., is a collection of research and development, production and sales. The national high-tech enterprises has a wide variety of products : tipping paper, food medical paper, interleaving paper, decoration paper and other products. Holding a subsidiary (Zhejiang Kaifeng Specialty Paper Co., Ltd.),Kaifeng was successfully listed on the new OTC market with the stock code 835427 in 2015.

At this time, Kaifeng has 5 paper production lines and 1 paper processing line. It's product sales are in the forefront of China, and the market of its tipping base paper covers many provinces, such as Yunnan, Guangdong, Anhui, Henan, Zhejiang, Jiangsu, Guangxi, Shandong, Hubei, Xinjiang, Shaanxi, Heilongjiang, Jilin, Guizhou, Fujian and so on. Although Kaifeng has achieved many high-profile achievements, the company is still committed to the continuous development of specialty papers for new applications.

Kaifeng has has built a domestic first-class specialty paper production line, due to its successively introduced key production equipment and online testing equipment with international advanced level from Germany, the United States, Italy and other countries. Combined with DCS system, QCS system and ERP system, Kaifeng has established an automated assembly line to realize mass production of customized specialty paper products. Kaifeng has always paid attention to the environmental protection of products.To improve the green level of products, Kaifeng invested a lot of manpower and funds in technology R&D, raw material procurement, and equipment introduction.And our efforts in environmental protection have also been recognized by the society. Kaifeng was honorably rated as "National High-tech Enterprise", "National Green Factory", "Well-known merchant brand in Zhejiang Province", and has obtained more than 30 patents related to green manufacturing.

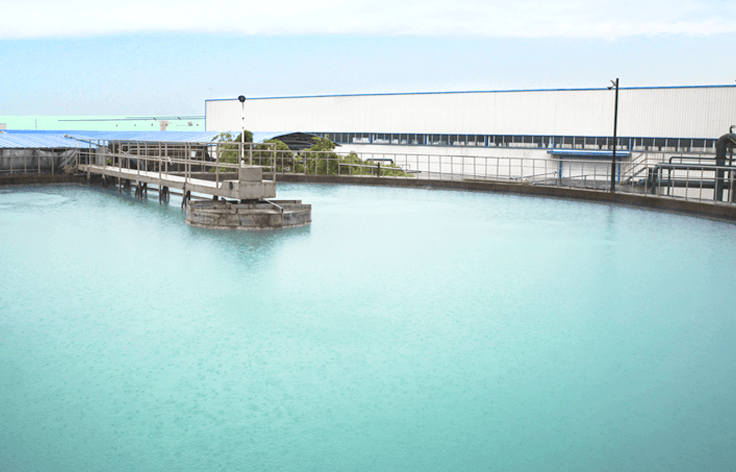

Kaifeng plans to build a 10MW solar photovoltaic power station. At present, the first phase has been connected to the grid with 5.5MW, and the annual power generation capacity of the project is 5 million kWh.Kaifeng is the first to apply large-scale ultrafiltration facilities in the field of wastewater treatment and to introduce international advanced membrane treatment technology. The reuse rate of white water during papermaking has been increased from 40% to 95%, which has greatly improved the factory's green manufacturing level and has great significance to promote in the specialty paper industry.

Since its establishment, Kaifeng has strictly complied with national laws and regulations, industrial policies and design standards in infrastructure. In terms of management system, Kaifeng actively introduces advanced management systems such as quality management system, environmental management system, occupational health, energy management system, integrated management system of informatization and industrialization to implement standardized management. In terms of energy and resource input, the company improves the utilization efficiency of resources and energy through technological transformation, adjustment of product structure, strengthening of management and other means. It has carried out a lot of practice in the selection of raw materials, product design, production process, waste resources and other links. Its raw material utilization rate, index of product energy consumption and pollutant discharge are all at the leading level in the industry. It's raw wood pulp has been certified by FSC. In addition, a full life cycle management is implemented on the main materials in the company.

Kaifeng has won the titles of "Zhejiang Green Enterprise", "Zhejiang Demonstration Enterprise of Industrial Circular Economy", "Zhejiang Water Saving Enterprise", and "Zhejiang Energy Measurement Demonstration Unit".The manufacturer is committed to building itself into a green benchmark in the specialty paper industry and leading the green development of the specialty paper-related industries.

No. 30, Jinxing Avenue, Longyou Industrial Park, Quzhou City, Zhejiang Province,China

No. 30, Jinxing Avenue, Longyou Industrial Park, Quzhou City, Zhejiang Province,China

Follow WeChat Official Accounts

浙公网安备

33082502000267号

浙公网安备

33082502000267号