How are Cigarette Tipping Base Papers Made?

Cigarette tipping base paper plays a crucial role in the production of cigarettes, serving as the outer layer of the filter.

It combines functionality, durability, and aesthetic appeal, contributing to cigarettes' structural integrity and visual identity.

This article explores the materials, manufacturing process, and quality standards behind this specialized paper.

1. What is Cigarette Tipping Base Paper?

Cigarette tipping base paper is a specially designed type of paper used to encase the filter tip of cigarettes.

This paper is meticulously engineered to ensure durability, allowing it to withstand the rigors of manufacturing and handling.

Its breathability is carefully controlled to regulate airflow, which can influence the smoking experience.

Additionally, tipping base paper is designed to seamlessly integrate with other cigarette components, ensuring compatibility with high-speed production processes and enhancing the overall functionality and aesthetics of the final product.

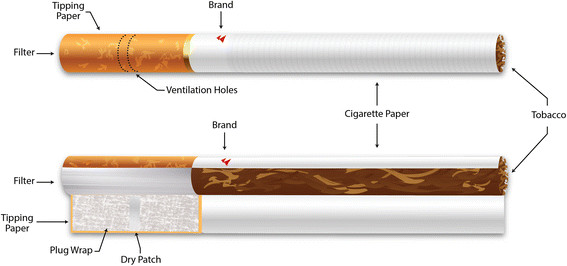

The Role of Tipping Base Paper in Cigarette Structure

Tipping base paper is the outermost layer of the cigarette filter, designed to encase and protect the filter tip.

This component plays a vital role in a cigarette's structure and functionality.

- Protection: The paper safeguards the filter, preventing tearing or damage during use or handling and ensuring the cigarette's structural integrity.

- Airflow Regulation: Through the use of micro-perforations, the tipping paper regulates airflow into the cigarette, helping to control the smoking experience by adjusting draw resistance and filtration efficiency.

2. What Goes Into Tipping Base Paper?

The composition of tipping base paper is to meet the technical and appearance requirements.

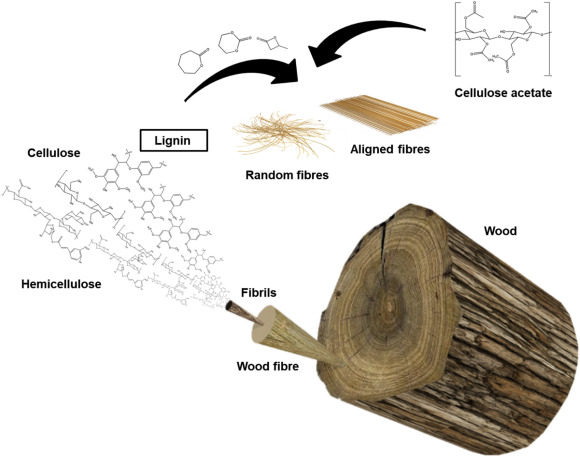

Cellulose Fibers

- The main component is cellulose fibers derived from wood pulp or other plant-based sources, for example, pine, oak, birch, and even bamboo.

- Cellulose is a polysaccharide composed of long chains of glucose molecules, which form a strong fibrous structure through hydrogen bonds and other intermolecular interactions. As a result, it naturally possesses high mechanical strength. Additionally, cellulose fibers in plants are typically long, allowing them to interweave into a dense fiber network, increasing structural stability. Finally, after processing, cellulose can form paper with the appropriate flexibility, enabling it to bend and stretch during the rolling process without easily breaking.

Additives and Coatings

- Calcium Carbonate: This additive improves the paper’s opacity and printability, making it suitable for intricate designs and branding.

- Functional Coatings: Specialized coatings enhance properties such as water resistance, smoothness, and air permeability.

- Micro-Porous Layers: These allow controlled airflow, optimizing the cigarette's draw resistance and filtration.

3. How Are Cigarette Tipping Base Papers Made?

The production of cigarette tipping base paper is highly specialized, involving several periods.

Pulp Preparation

- Fiber Processing: Wood or plant fibers are processed into pulp through chemical or mechanical means. The fibers are broken down and refined to achieve a smooth consistency.

- Cleaning and Refining: Impurities such as lignin and other non-cellulose components are removed, resulting in high-purity cellulose pulp suitable for papermaking.

Sheet Formation

- Sheet Creation: The refined pulp is spread onto a moving wire mesh to form a thin sheet. Water is drained, and the sheet is pressed to remove excess moisture.

- Drying: The sheet passes through heated rollers or drying cylinders to achieve the desired dryness and thickness.

Surface Treatment

- Coating Application: The dried paper is coated with functional additives to enhance its durability, printability, and porosity.

- Micro-Perforation: Tiny holes are added to regulate airflow and improve the cigarette’s smoking properties.

Customization Design

- Printing: Advanced printing techniques are used to apply branding elements, patterns, and colors to the paper.

- Special Effects: Some papers may include metallic finishes, embossed textures, or other design features to enhance visual appeal.

4. What Quality Standards Are Required to Produce Tipping Paper?

Ensuring the quality of cigarette tipping base paper is essential for both functionality and compliance with industry regulations.

- Porosity: The paper's porosity must be carefully controlled to allow the appropriate level of airflow, ensuring a consistent smoking experience.

- Strength: The paper must resist tearing during manufacturing and usage while maintaining flexibility.

- Safety Compliance: All materials and additives must meet regulatory standards for safety and non-toxicity.

- Environmental Standards: Many manufacturers adhere to eco-friendly practices, such as using recyclable materials and minimizing production waste.

Conclusion

Cigarette tipping base paper's production involves sophisticated techniques, from pulp preparation to surface treatment and customization, ensuring the paper has stringent quality and safety standards. Knowing the details of tipping base paper production sheds light on its significance in the cigarette paper industry and its potential.