Stainless steel interleaving paper

Stainless Steel Interleaving Paper is a specialized protective paper used between stainless steel sheets to prevent scratching, staining, and surface damage during stacking, storage, or transportation. It features excellent strength, low abrasiveness, and resistance to moisture and chemicals, ensuring the surface quality of finished metal products is maintained.

Product Feature:

It has the characteristics of high surface cleanliness, less ion leaching, neutral paper and high temperature resistance.

Product Application:

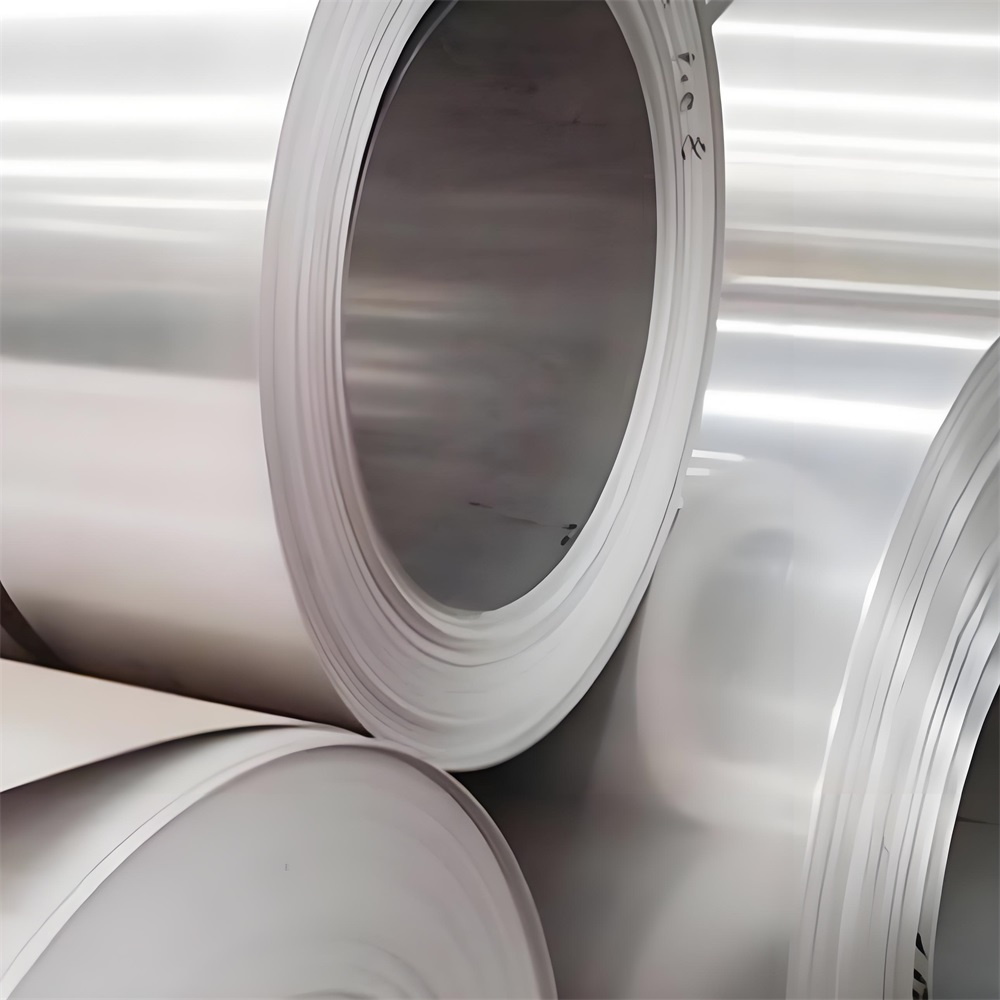

Stainless steel interleaving paper is mainly used in the cold-rolled stainless steel sheet production process (between each process) and the finished liner to prevent the stainless steel roll in the process of crimping and transfer due to slip, extrusion, friction and other friction between the plate surface caused by scratches or damage.

Application Scenario

Product Details

Properties and Technologies

Mechanical Optimization

Tensile strength ≥80N/15mm (longitudinal), ensuring no breakage at high speed winding (maximum line speed 800m/min);

Surface smoothness ≤0.5μm Ra, micron-level contact surface realized by super-calendering process to avoid transferring its own texture to the steel plate;

Elongation control (2-4% longitudinal, 6-8% transverse), matching the elastic modulus of deformation of stainless steel plate.

Chemical Compatibility

pH neutral (6.5-7.5) to avoid acid-base reaction with stainless steel surface passivation film (Cr₂O₃);

Low chloride ion content (≤30ppm) to prevent induced stress corrosion cracking (SCC) of austenitic stainless steel;

Anti-static treatment (surface resistance 10⁶-10⁸Ω), eliminating dust pollution caused by electrostatic adsorption.