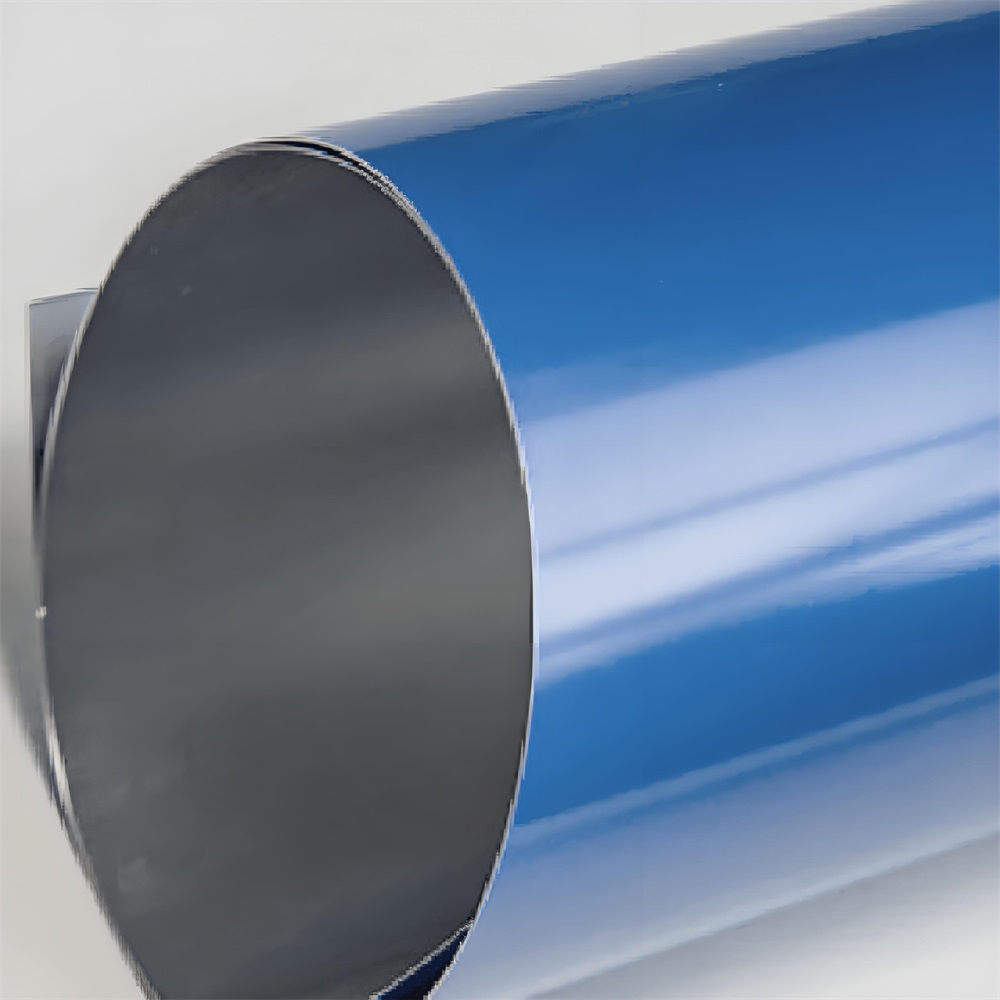

CTP interleaving paper

CTP Interleaving Paper is a high-quality protective sheet used between Computer-to-Plate (CTP) printing plates to prevent scratches, dust contamination, and surface damage during storage and handling. It offers smooth surface texture, excellent moisture resistance, and minimal dust generation, ensuring the integrity and longevity of CTP plates for optimal printing performance.

Product Feature:

It has the characteristics of high surface cleanliness, flat paper, slightly acidic, and high strength.

Product Application:

Production and protection of CTP plate

Application Scenario

Product Details

In the CTP workflow, imaging plates are subjected to rigorous environmental and mechanical stresses that compromise their lithographic integrity. CTP interleaving paper, also CTP plate protection paper, or CTP plate isolation paper is designed to mitigate these risks. Composed of tailored materials and coatings, it acts as a barrier against contaminants, static discharge, and physical abrasion, thereby preserving the plate’s imaging layer and chemical stability. Its adoption is integral to achieving consistent print output and prolonging plate lifespan.

Characteristics

Moisture Barrier Properties

High-performance CTP interleaving paper exhibits superior hydrophobicity, forming a protective shield against ambient humidity.

This prevents oxidation, microbial growth, or hydrolysis of the plate’s photosensitive coating—common issues that degrade imaging accuracy and print durability.

Advanced moisture-resistant treatments ensure stability in diverse climatic conditions during transit and storage.

Static Dissipation Capabilities

Electrostatic charges generated during plate handling attract particulate contaminants, leading to print defects.

Anti-static agents embedded in the paper’s matrix neutralize surface charges, minimizing dust adhesion and ensuring plate cleanliness.

This feature is critical for high-resolution plates used in premium graphic and packaging applications.

Surface Topography and Mechanical Strength

The paper’s engineered smoothness (measured via Bekk or Parker Print Surf testing) prevents microscratches during plate contact, while its calibrated thickness (typically 40–80 gsm) balances flexibility and rigidity.

This design provides structural support during stacking without imposing undue mechanical stress on delicate emulsion layers.

Delamination Efficiency

Optimized peel strength ensures effortless, residue-free separation of the interleaf from the plate surface.

Proprietary coatings reduce adhesive transfer risks, eliminating paper debris that could interfere with plate mounting or ink transfer.

Environmental and Safety Compliance

Manufactured under ISO 14001 and REACH standards, CTP interleaving papers utilize non-toxic, recyclable substrates.

Hazardous substances such as phthalates and heavy metals are excluded to ensure occupational safety and eco-friendly disposal.

Customization for Plate Variants

Tailored solutions exist for distinct CTP technologies (e.g., thermal, photopolymer, violet laser).

Color-coded edges, QR codes, or UV-reactive markers enable rapid plate identification, while specialty coatings (e.g., low-lint, acid-free) address niche requirements in high-speed or archival printing.

Applications

Plate Manufacturing and Logistics

Post-production, interleaving paper is laminated onto plates to prevent surface abrasion and chemical exposure during shipping.

Its moisture barrier properties are vital for intercontinental transport, where temperature fluctuations risk condensation.

Storage and Inventory Management

In print facilities, interleaved plates are stored vertically or in climate-controlled cabinets.

The paper’s anti-static properties reduce dust ingress while color-coding streamlines inventory tracking and batch reconciliation via integrated ERP systems.

Pressroom Workflow Integration

Before plate mounting, operators remove the interleaf to expose a pristine surface.

The paper’s clean release ensures no adhesive residue, critical for precise registration on press cylinders.

Post-removal, plates undergo final QC checks for defects under controlled lighting.

Sustainability and Waste Reduction

Recyclable interleaving papers align with circular economy initiatives, reducing landfill waste.

Some variants incorporate biodegradable coatings, appealing to eco-certified printers seeking ISO 16759 compliance.